Why You Need To Choose Professional Commercial Refrigeration Repair in Toronto

Why You Need To Choose Professional Commercial Refrigeration Repair in Toronto

Blog Article

Fixing Commercial Refrigeration Repair: Strategies for Quick and Effective Fixes

In the world of commercial refrigeration, the demand for swift and precise troubleshooting methods is extremely important. When a refrigeration unit breakdowns, the repercussions can be pricey and turbulent to service operations. Understanding the usual concerns that pester commercial refrigeration systems and having a toolkit of diagnostic techniques available can make all the distinction in quickly identifying and fixing problems. As we navigate through the ins and outs of repairing industrial refrigeration fixing, we will discover the vital methods for fixing issues successfully, making certain that services can maintain ideal cooling efficiency and minimize downtime.

Common Business Refrigeration Problems

Industrial refrigeration systems frequently encounter a variety of operational problems that can disrupt their effectiveness and efficiency. One prevalent issue is improper temperature level control, which can lead to food spoilage and waste if not promptly dealt with.

Furthermore, cooling agent leakages present a significant concern as they not just influence the air conditioning capacity of the system yet also add to ecological harm. Identifying and fixing leakages quickly is important to avoid further damages and ensure conformity with guidelines. Additionally, unclean condenser coils can impede warmth transfer, requiring the system to work more difficult and consume even more power. Routine cleaning and upkeep can help avoid this problem and prolong the life-span of the refrigeration system.

Analysis Devices and Methods

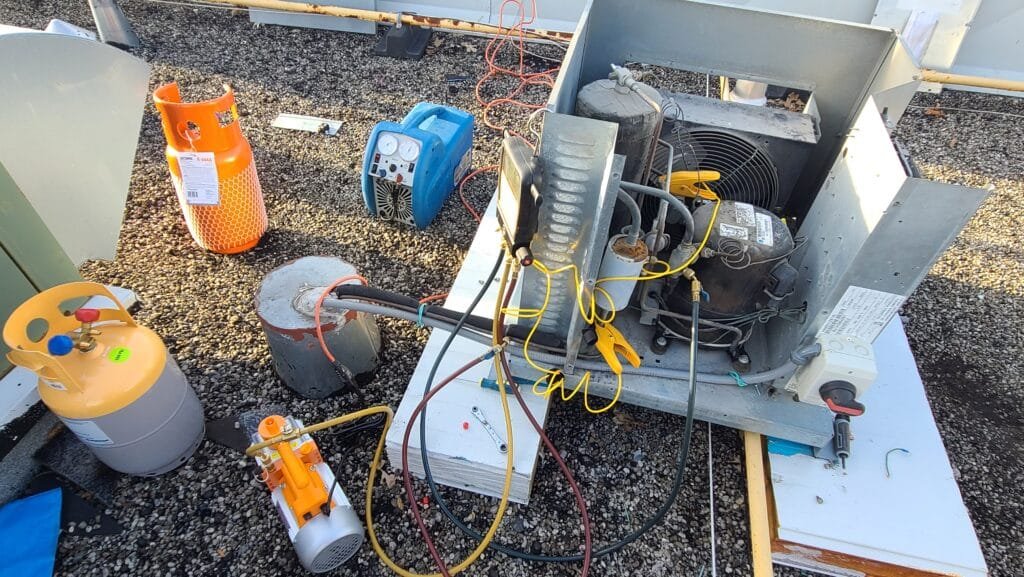

Reliable troubleshooting of commercial refrigeration systems relies greatly on making use of specialized analysis devices and methods to identify and resolve underlying issues successfully. One vital analysis device is the multimeter, which assists professionals measure voltage, present, and resistance in various components such as compressors, motors, and defrost heating units. Thermostats are also critical for examining temperature differentials across the system to pinpoint possible troubles like cooling agent leaks or improper air movement. Furthermore, leak discovery devices like digital leakage detectors or ultraviolet color kits are important for finding cooling agent leakages that can lead to system ineffectiveness.

Information loggers can be used to keep track of system performance over time and discover fads that might indicate persisting troubles. By incorporating these diagnostic tools and methods, technicians can efficiently fix industrial refrigeration systems and give quick and accurate repair services, minimizing downtime and guaranteeing ideal system efficiency.

Quick Fixes for Refrigeration Troubles

When encountered with refrigeration troubles, specialists can execute quick fixes to resolve usual issues quickly and effectively. If the refrigeration system is not cooling correctly, inspecting and adjusting the thermostat setups might supply a quick option before even more extensive troubleshooting is required. By carrying out these quick solutions, service technicians can deal with common refrigeration issues efficiently and maintain industrial refrigeration systems running efficiently.

Preventative Maintenance Tips

Applying a proactive upkeep timetable is essential for ensuring the long life and optimal efficiency of industrial refrigeration click over here systems. Regular maintenance not just helps protect against expensive breakdowns yet also makes sure that Related Site the equipment runs efficiently, saving power and decreasing total operating expense. Here are some preventative maintenance pointers to keep industrial refrigeration systems running efficiently:

Check and Replace Filters: Unclean filters can limit air flow, making the system job tougher and potentially creating damage. Examine and replace filters regularly to stop problems.

Inspect Seals and Gaskets: Dripping seals and gaskets can result in temperature level fluctuations and power wastage. Checking and replacing damaged seals can aid maintain constant temperature levels.

Expert Assistance and Services

To preserve the optimal efficiency accomplished with regular preventative upkeep, seeking professional support and solutions for commercial refrigeration systems is crucial. Professional professionals possess the proficiency and specialized understanding required to detect and deal with complex concerns effectively. When encountering tough refrigeration issues, counting on expert assistance can save both money and time over time.

Expert solutions provide advantages such as access to sophisticated devices and devices, ensuring that repairs are executed successfully. Additionally, professionals are trained to stick to sector regulations and safety and security standards, minimizing the danger of crashes and guaranteeing compliance with lawful needs.

Verdict

To conclude, repairing commercial refrigeration repair service requires a methodical approach to determining usual issues, using diagnostic tools and strategies, carrying out quick solutions, and focusing on preventative maintenance. Specialist assistance and services may be needed for more facility issues - commercial refrigerator repair. By adhering to these strategies, companies can guarantee their refrigeration systems run successfully and effectively, minimizing downtime and prospective losses

Recognizing the usual concerns that afflict commercial refrigeration systems and having a toolkit of diagnostic methods at your disposal can make all the distinction in promptly recognizing and fixing issues.Reliable troubleshooting of commercial refrigeration systems relies heavily on using specialized analysis tools and techniques to determine and solve underlying issues successfully. By combining these diagnostic tools and methods, service technicians can successfully repair business refrigeration systems and supply quick and precise repairs, reducing downtime and guaranteeing optimum system efficiency.

By executing these fast fixes, professionals can attend to usual refrigeration problems successfully and maintain industrial refrigeration systems running smoothly.

In addition, expert support can help expand the life expectancy of industrial refrigeration systems by recognizing prospective issues prior to they intensify.

Report this page